Solutions

Our custom-engineered solutions are designed to meet the unique needs of each application, including activation under various time-temperature profiles, adhesion to different substrates, and resistance to certain environmental exposure conditions.

Injection-Molded Parts

Injection-Molded Parts

- Foamable sealant material combined with nylon carrier for three-dimensional cross-sections for a variety of sealing applications

- Capable of precise location sealing

- Available with optional clips and a variety of expansion rates

Co-Extruded Parts

Co-Extruded Parts

- Expanding sealant extruded around nylon carrier core, cut to width

- Ideal for narrow cavities sealing

- Ideal for precise location sealing

- Extruded parts with integral attachment

- Low tooling costs compared to injection molding

- Ideal for high-volume applications

Die-Cut / Assembled Parts

Die-Cut / Assembled Parts

- Expanding sealant material

- Low tooling cost

- For large and small complex cross-sections

Extrude in Place (XIP sealants)

Extrude in Place (XIP sealants)

XIP™ is the process of extruding and applying a dry-to-touch L&L sealant material to a metal substrate that is part of the vehicle construction using an automated robotic system.

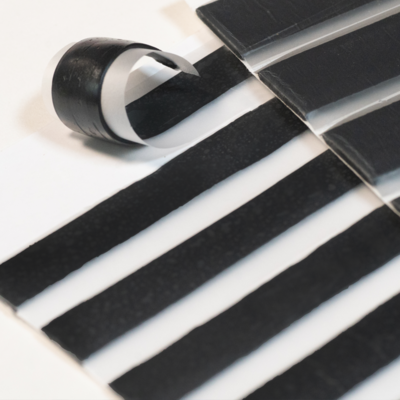

Tapes

Tapes

Extruded Pressure-Sensitive Foaming Tapes.

- Excellent adhesion and highly flexible

- Low or no tooling cost

- Custom dimensions for different cavity sizes

- Range of volumetric expansion rates available (up to 1,200%)

- Weld-through version available

Resources

Download our resources to find out more on how our Heat Activated Sealants can be tailored to your needs to prevent the intrusion of water, air, dust, and fumes and to improve acoustic performance.